Cable Assemblies for Industries

Molded Deutsch Cable Assemblies have been in the market for more than 70 years since 2011. DEUTSCH Assembly is high-performance items created for aviation, material handling, military, automotive, agricultural, mining, architecture, sports, maritime industries, and more. They are well-known for their use in the driest and most extreme situations. These environmentally-sealed electrical connectors offer a strong, secure cable-to-cable connection, preserving connector engagement in demanding environments applications, and withstanding both high moisture and temperature. They are utilized in applications ranging from engines to braking systems. For car transmissions to on-highway applications, the DEUTSCH assembly offers dependable connector performance.

For cable-to-cable, cable-to-board, and cable-to-device needs, DEUTSCH DT connections are created. This series offers tough quality and field-proven dependability for the engine or transmission, the chassis, and the interior of the car. The DT design’s advantages include flexible design options, variable pin configurations, and optional flange installation. The connections can survive circumstances of severe temperature and moisture due to silicone back wire, interface seals, and thermoplastic housings that give a wide operating temperature range.

Benefits

Environmentally sealed DEUTSCH assemblies are employed in harsh environment applications where even a slight connection loss may be crucial. Under the hood, on motor controllers and solenoid connectors, DEUTSCH connectors deliver stability and performance. They provide tough quality and field-proven efficiency. The designer can employ numerous size 16 contacts, each with a 13 amp continuous capability, in a single shell.

Applications of Molded Deutsch cable assemblies

The electrical systems of your vehicles and equipment must withstand demanding conditions and all-weather situations in heavy industries, whether they are on the road, in a farm field, or at a job site. Diagnostic costs for electrical system failures can be high, and downed equipment can halt operations completely. We have created a variety of connections with strong heat, moisture, chemical, impact, and vibration resistance. In some of the worst settings, Molded Deutsch Cable Assemblies have consistently performed.

Understanding RF Cable Assemblies

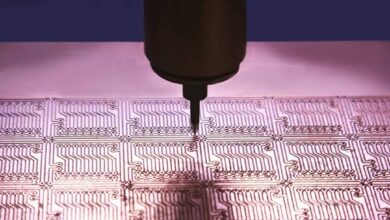

RF cable assemblies are pre-assembled at the manufacturer’s place in various sizes to accommodate a range of RF applications, such as testing, signal transmission, and signal reception. It can move a variety of signals from the source to the intended position with the least amount of interference or loss since it is built to convey an RF signal via its center contact, which is frequently composed of copper or another highly conductive element. In combination with antennas, Micro-Coaxial Receptacles and Cable Assemblies provide a cost-effective end-to-end RF solution. In a wide range of applications, including consumer electronics, medical systems, smart home appliances, and more, these devices offer great electrical performance to build a dependable RF or wireless connection to a primary printed circuit board.

When developing testing capability and managing legacy initiatives, test engineers and the maintenance team must balance cost and risk. In addition to managing new and frequently unbudgeted corporate or governmental mandates, aerospace and defense organizations around the world are regularly required to learn and integrate new RF and wireless technologies. In some cases, legacy test equipment is even required to be maintained for years longer than anticipated. To satisfy the demands of your particular operational needs, RF Cable Assemblies are prebuilt to support coaxial and micro coaxial fits in a wide range of frequency ranges. These cable assemblies will guarantee precise measurements and monitoring in a variety of applications demanding low signal loss, and stability.

Radiofrequency (RF) cable assemblies might be pre-assembled, fixed length, or standard. They are created in standard lengths or standard configurations. These assemblies come in curved, hand-formed, flexible, and semi-rigid shapes. They can also be designed to meet specific needs. These RF cables come in a range of diameters, weights, and strict tolerances, making them suitable for usage in a range of commercial and industrial applications.