A Liquid-Level Selection Guide: Types, Applications, and Features

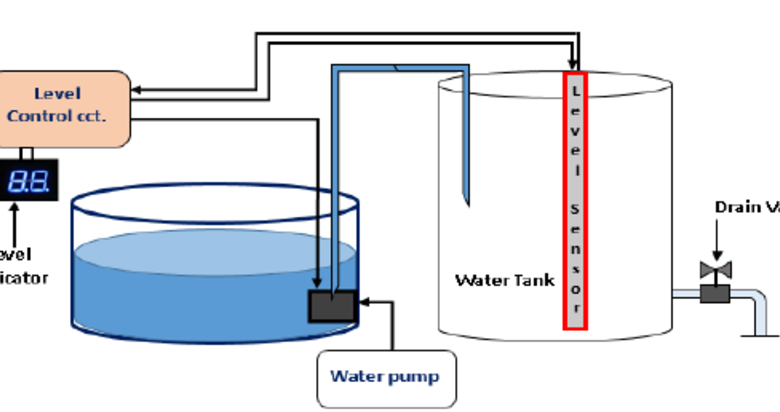

A liquid-level system is a device used to measure and control the level of liquids in tanks, reservoirs, and other containers. Liquid-level systems are used in various applications, including industrial process control, environmental monitoring, agriculture, residential and commercial buildings, and transportation.

There are several types of liquid-level systems, including float-based, pressure-based, ultrasonic, capacitance-based, and radar-based systems. Each type of system has its own unique features and benefits, and the most appropriate type of system will depend on the specific application and requirements.

Types of a Liquid-Level System

There are several types of liquid-level systems, including:

- Float-based liquid level systems: These systems use float sensors that fluctuate with the liquid level. The float is connected to a mechanical or electrical device, like a lever or a sensor, to measure and control the liquid level.

- Pressure-based liquid level systems: They use a pressure sensor to measure the hydrostatic pressure of the liquid.

- Ultrasonic liquid level systems: These systems use ultrasound waves that measure the distance to the surface of the liquid. The time taken by the ultrasound waves to move through the sensor to the liquid surface and back determines the liquid level.

- Capacitance-based liquid level systems: They use a capacitor to measure the change in capacitance as the level of the liquid changes. The change in capacitance calculates the liquid level.

- Radar-based liquid level systems: These systems use radar waves that measure the distance to the surface of the liquid. The time it takes for the radar waves to travel from the sensor to the liquid surface and back is used to calculate the liquid level.

Liquid-level systems are relevant in various applications, such as industrial process control, environmental monitoring, agriculture, residential and commercial buildings, and transportation.

Application of a Liquid-Level System

Liquid-level systems measure and control the level of liquids in tanks, reservoirs, and other containers using a liquid level indicator. They are applicable in various sectors like the following:

- Industrial process control: the systems monitor and control the level of liquids in tanks and reservoirs. This can include monitoring the chemical levels, fuels, water, and other liquids used in the production process.

- Environmental monitoring: Liquid-level systems can track the liquid levels in natural bodies of water, such as lakes, rivers, and oceans. This can help identify trends in water levels and alert authorities to potential flooding or other environmental hazards.

- Agriculture: They surveil and control the water levels and liquids in irrigation systems, greenhouses, and other agricultural environments.

- Residential and commercial buildings: Liquid-level systems are often used in residential and commercial buildings to monitor and control the levels of water in tanks, such as those used for the storage of potable water or for irrigation.

- Transportation: the systems monitor the levels of fuels and other liquids in tanks on vehicles, such as cars, trucks, and airplanes. This helps to ensure that there is enough liquid to power the machine and prevent spills or leaks.

Features of a Liquid-Level System

The features of a liquid-level system can vary depending on the specific type and application. However, some features of liquid-level systems include the following:

- Accuracy: A liquid level system should accurately measure the liquid level within a particular tolerance range.

- Range: The range of a liquid level system refers to the minimum and maximum levels it can measure.

- Resolution: The resolution of a liquid level system refers to the smallest increment measurable.

- Response time: The response time of a liquid-level system refers to how quickly it can respond to changes in the liquid level.

- Robustness: A liquid-level system should withstand harsh conditions, such as extreme temperatures, vibration, and moisture.

- Compatibility: A liquid level system should be compatible with the liquid type it’s measuring and the environment in which it is used.

- Cost: The cost of a liquid-level system can vary depending on its features and the complexity of the application.

Liquid-level systems can perform a variety of functions, including monitoring the level of a liquid in real-time, controlling the flow of a liquid into or out of a container, and alerting operators to low or high levels of a liquid. Overall, liquid-level systems play a vital role in many industries and applications, helping to ensure the efficient and safe use of liquids and to protect people and the environment.

For more valuable information visit this website