Elevating Industrial Efficiency: Exploring the Evolution of Overhead Cranes in Modern Manufacturing

Picture a bustling manufacturing floor – a symphony of activity, where raw materials are transformed into intricate products that power our world. In the midst of this organized chaos stands a silent yet mighty hero: the overhead crane. These mechanical giants have come a long way from their humble beginnings, evolving into essential tools that optimize industrial efficiency in ways that were once unimaginable. In this article, we’ll take a captivating journey through the evolution of overhead cranes, uncovering how they’ve transformed modern manufacturing landscapes.

1. The Genesis: Early Overhead Cranes

Our story begins with the early days of manufacturing, where basic cranes hoisted heavy loads using sheer muscle power. These rudimentary cranes, often operated by a team of workers, laid the groundwork for what was to come. While effective for their time, they were far from the precision and automation we witness today.

2. Industrial Revolution: A Shift in Perspective

With the dawn of the Industrial Revolution, manufacturing transformed into a mechanized marvel. Overhead cranes began adopting mechanical advancements, utilizing pulley systems and steam-powered engines. This shift marked a turning point, as cranes started to evolve from manual labor facilitators to semi-automated workhorses.

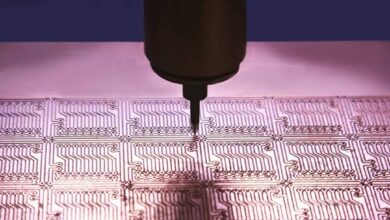

3. Precision Takes Flight: Introduction of Electric Overhead Cranes

The introduction of electricity brought about a paradigm shift in crane technology. Electric EOT cranes entered the scene, offering enhanced control and precision. These cranes were capable of more intricate movements, making them vital for industries that demanded finesse in material handling.

4. The Automation Revolution: Overhead Cranes of Today

Fast forward to the present, and overhead cranes have undergone a revolutionary transformation. Automation and advanced control systems have revolutionized their capabilities. Cranes can now be operated remotely, with operators guiding movements from a safe distance. Sensors and cameras provide real-time feedback, ensuring precise and safe handling of materials.

5. Tailoring to Industry Needs: Customization in Modern Overhead Cranes

One of the most remarkable aspects of modern overhead cranes is their adaptability. They can be tailored to suit industry-specific needs. Whether it’s the automotive sector requiring high-speed movements or the pharmaceutical industry demanding contamination-free handling, bridge cranes are engineered to excel in diverse environments.

Waste Handling:

Waste handling is a gritty, demanding industry that requires robust solutions capable of handling heavy loads and enduring harsh conditions. Customized cranes for waste handling possess several distinct features:

Durability: These cranes are constructed using heavy-duty materials that can withstand exposure to waste materials, corrosive substances, and the rigors of outdoor environments.

Specialized Grapples or Magnets: Waste materials come in various forms, from loose debris to bulky objects. Cranes in this industry are equipped with specialized grapples or magnets designed to securely grip different types of waste materials, facilitating efficient collection and disposal.

Load Limiting Systems: To ensure safe operation, waste handling cranes often incorporate load limiting systems that prevent overloading and instability.

Weatherproofing: Since these cranes are exposed to the elements, weatherproofing features like corrosion-resistant coatings and seals are crucial to extend their operational lifespan.

Steel Plants:

Steel plants operate under extreme conditions of high temperatures and heavy loads. Customized cranes for steel plants are engineered to withstand these challenges while optimizing efficiency:

Heat-Resistant Materials: Cranes in steel plants are constructed from heat-resistant materials that can endure the intense temperatures generated during steel production processes.

Protective Coatings: Specialized coatings are applied to protect the cranes from the corrosive effects of molten metal and harsh chemicals.

High Lifting Capacities: These cranes are designed with high lifting capacities to handle heavy steel components like ingots, coils, and ladles.

Reinforced Structures: The structural integrity of these cranes is reinforced to ensure stability and safety while operating in demanding environments.

Paper Industry:

The paper industry demands precision and gentle handling to prevent damage to delicate paper rolls and machinery. Customized cranes for this sector emphasize accuracy and care:

Precision Controls: These cranes are equipped with precision control systems that allow operators to handle paper rolls with minute adjustments, reducing the risk of damage.

Anti-Sway Technology: To minimize swaying and swinging of loads, anti-sway technology is integrated into these cranes, ensuring that paper rolls are moved smoothly and without disturbances.

Ergonomic Design: Operators often need to navigate confined spaces within the paper mill. Cranes in this industry are designed with ergonomic features to enhance operator comfort and control.

6. Enhancing Safety: Advanced Safety Features

Safety has always been a paramount concern in manufacturing. Modern overhead cranes are equipped with advanced safety features like collision detection systems, emergency stop mechanisms, and load monitoring sensors. These features mitigate risks, ensuring both the safety of operators and the integrity of materials being handled.

7. Beyond Heavy Lifting: Overhead Cranes in the Digital Age

We’re now entering the era of the Internet of Things (IoT) and Industry 4.0. Overhead cranes are no exception to this digital transformation. They’re being integrated into interconnected systems, enabling data-driven insights and predictive maintenance. These smart cranes not only move materials but also contribute to data-driven decision-making.

In the rapidly evolving landscape of material handling, the integration of digital technology has become paramount. Leading the charge in this digital age are renowned overhead crane manufacturers such as Konecranes, Demag Crane, Dafang Crane, and KS Crane. These industry giants have demonstrated a remarkable ability to embrace the digital transformation, seamlessly melding cutting-edge technologies with traditional engineering prowess. From IoT-enabled monitoring and predictive maintenance to real-time data analytics, these manufacturers have not only mastered the art of lifting heavy loads but have also unlocked the potential of data-driven insights, elevating overhead cranes to the forefront of the digital revolution.

8. Sustaining Excellence: The Future of Overhead Cranes

The evolution of overhead cranes continues as innovation marches forward. The future promises even smarter, more efficient, and sustainable cranes. Expect to see further integration with emerging technologies like artificial intelligence, enabling cranes to adapt and optimize their operations in real-time.

Raising the Bar in Manufacturing

The journey of overhead cranes from their manual beginnings to their current state of automation is a testament to human ingenuity. These mechanical marvels have transformed manufacturing landscapes by optimizing efficiency, enhancing safety, and boosting productivity. As we stand at the cusp of a digital era, bridge cranes are poised to continue raising the bar, shaping the future of manufacturing, one precise lift at a time.

For more valuable information visit this website